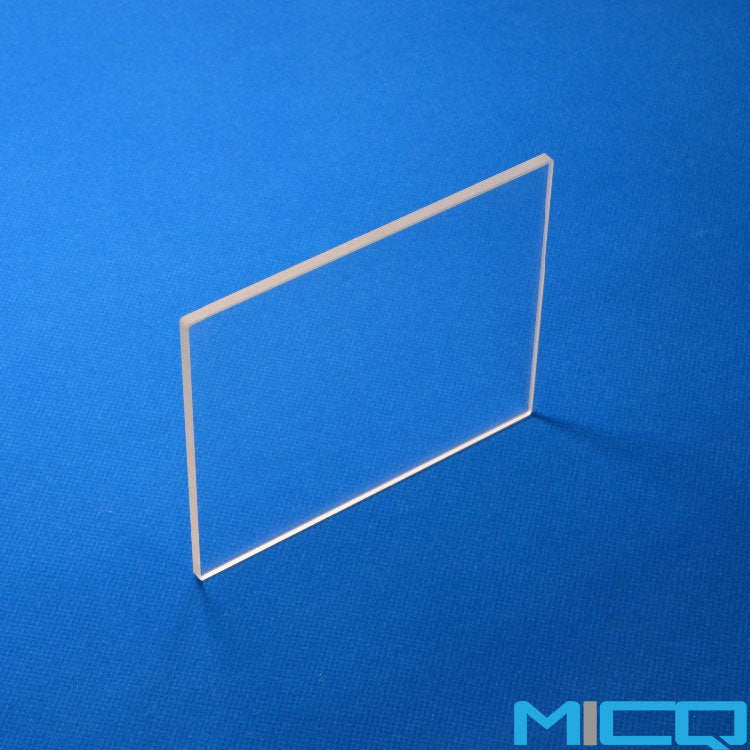

General manufacturing processes of the quartz plates

Quartz plates are a versatile material that can be used to manufacture a variety of products, including electronic devices, optical instruments, and crystal oscillators. The manufacturing process of quartz plates is intricate and necessitates the completion of numerous procedures. The subsequent discussion will provide a comprehensive overview of the quartz plate production process.

- Raw materials preparation

It is imperative that high-quality quartz ore is prepared as the raw materials, in addition to obtaining quartz particles that are suitable for processing following crushing, screening and other treatment.

- High temperature preparation

The quartz particles are melted in a quartz furnace at a high temperature, and then the molten quartz is made into a thin sheet by casting, stretching or film exfoliation.

- Cutting and grinding

Following the melting of the quartz glass, a cutting and grinding process is then required to cut it into the required size of quartz plate. The cutting process generally uses high-precision cutting machines to ensure that the size and flatness of the quartz plate meet the required specifications. The quartz plates that have been cut should then be ground, using abrasive material with various particle sizes, to achieve the required surface finish and precision.

- Thermal treatment

Following the grinding of the quartz plate, a significant internal stress is produced. To enhance the stability and strength of the quartz plate, it must undergo a heat treatment process. The heat treatment process is typically divided into two stages. First, the quartz plate is heated in a high-temperature furnace to rearrange its lattice structure and release the internal stress. Then the quartz plate is cooled rapidly to fix its structure.

- Surface treatment

The surface treatment of the quartz plate is a critical step that directly impacts its performance and application. Typically, quartz plates undergo a series of processing procedures such as polishing, coating, and other related methods to enhance their light transmission, scratch resistance, and corrosion resistance. The polishing process typically involves the use of specialized polishing machinery and abrasives to ensure a smooth finish on the quartz plate. The coating process can be selected according to the specific requirements of different coating materials, such as silica and alumina, and so on.

- Inspection and packaging

The quartz plate then undergoes stringent quality and performance testing to ensure it meets the required standards. Common inspection methods include optical microscopy testing, surface quality evaluation, strength testing, and others. Upon successful completion of these tests, the quartz plate is packaged using materials such as plastic bags and foam boxes to safeguard it from external environmental factors.

The typical production process for quartz plates involves several stages, including raw material preparation, cutting and grinding, heat treatment, surface treatment, testing, and packaging. Each stage demands precise execution and high technical proficiency to guarantee the quality and performance of final products. With advancements in science and technology and continuous improvements in manufacturing processes, the production of quartz plates has evolved, leading to broader applications and new opportunities across various industries.