Innovation in the manufacturing process of quartz tubes

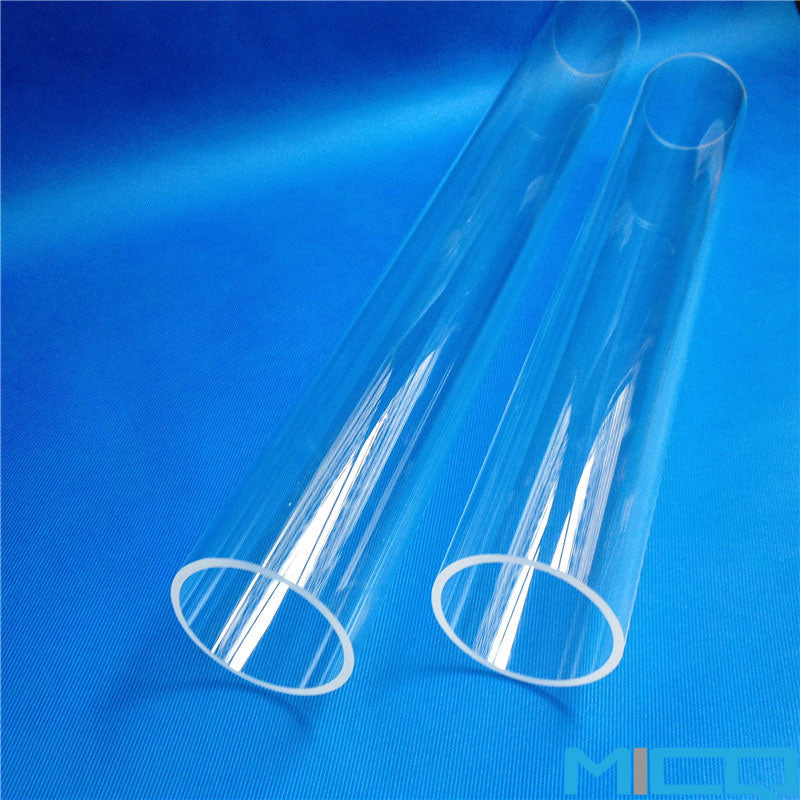

Quartz tubes are an important material widely used in scientific research, industry and medical fields. It has excellent high temperature resistance, corrosion resistance and excellent transparency, so it is widely used in the storage of chemical reagents, semiconductor manufacturing, optical fiber communication, life sciences and other fields. With the continuous development of science and technology, the manufacturing process of quartz tubes is also constantly innovating to meet the requirements of quartz tubes in various application fields.

- Innovation in material selection technology:

- Quartz tube material selection technology has always been the focus of attention in the quartz products industry. The manufacture of traditional quartz tubes mainly relies on natural quartz ore, but due to the scarcity and high cost of quartz ore, the manufacturing cost of quartz tubes is relatively high. Therefore, in recent years, some research institutions and enterprises have begun to study and develop the technology of synthetic quartz tubes, which reduces production costs and increases output by melting and molding synthetic quartz particles.

- The development of new pure quartz ores is also one of the innovative directions of quartz tube material selection technology. Traditional quartz tubes may be affected by impurities during the manufacturing process, thereby affecting product quality. Therefore, some researchers began to study and develop new types of quartz ores with higher purity to ensure the quality of quartz tube products.

- Innovation in melt forming technology:

- The traditional quartz tube melt forming process mainly relies on the melt forming of quartz blanks. This process has problems such as high energy consumption and low production efficiency. To solve these problems, some enterprises and research institutions have begun to research and develop new melt forming technologies, such as oxide coating molding technology, electron beam melting technology, etc. By improving the melt forming process, the production cost is reduced and the production efficiency is improved.

- Laserforming is an emerging direction of quartz tube melt forming technology in recent years. Laser forming technology uses a laser beam to heat the quartz blank to achieve precision forming of the quartz tube. Compared with traditional melt forming technology, laser forming technology has the advantages of high forming accuracy and high production efficiency, and has received widespread attention.

- Innovation in surface treatment technology:

- The surface treatment of quartz tubes has an important impact on their performance and application. Traditional surface treatment processes mainly include chemical oxidation, sandblasting, etc., which have problems such as uneven treatment effect and large surface roughness. To solve these problems, some companies and research institutions have begun to research and develop new surface treatment technologies, such as plasma polishing technology and chemical plating technology, to improve the surface finish and anti-fouling performance of quartz tubes.

- The application of nanomaterials is also one of the innovative directions of quartz tube surface treatment technology. Nanomaterials have a large specific surface area and unique physical and chemical properties, and can be used for surface modification of quartz tubes to make them have better corrosion resistance, wear resistance and optical properties.

In general, the manufacturing process of quartz tubes is constantly innovating, aiming to improve product quality, reduce production costs, and expand application areas. With the continuous emergence of new materials and new processes, the application potential of quartz tubes in various fields will continue to be tapped, providing a broader space for promoting industrial development and scientific and technological progress.